|

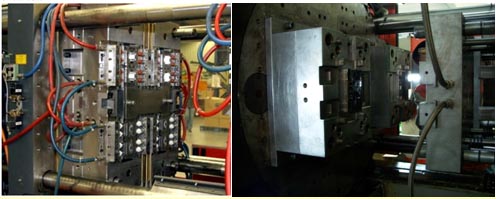

>> Injection

Room |

|

We have world-class

injection machines, Demag 14 set, ranging

from 80 tons to 285 tons. Nissei 14 set

,ranging from 20 tons to 100 tons. We also

provide from 350 tons to 850 tons to

molding. The Plastic Injection Manufacturing

service strictly follows the ISO 9001:2000

Quality Management System.

The outstanding quality, comprehensive

overall service and cost-effective

manufacturing capabilities |

|

|

Molding shop

Molding shop |

|

|

have

formed a solid basis upon which KYH has built up a

wide variety of long-term international

customers |

|

|

| |

|

>> Double Injection Room |

|

|

In

addition to the single-color injection

molding to meet the demands of customer, we

also provide two shot injection molding

service .Two shot molding (2k) is both molded parts can be molded in the same

tool. This is achieved by creating tools

that have two separate component cavities

and can be rotated through 180°, The

difference both cavities of tool isn’t

move, Just the same both cores of tool to

rotated through 180° ,so that they line up

with the two injection units. In the first

step of the process a pre-molded part is

created in the first cavity. |

|

The tool

then opens to allow the necessary rotation

through 180° to the secondary position. Now

when the tool closes again the pre-molded

part is in the second position so that it

can be finished with the second injection.

During this second phase the another, pre-molded

part, is being produced in the first

position so that the process is a continuous

cycle |

|

Two shot

molding combines two plastic materials

injected into the mold to form a single part

with two visible colors. This process allows

for clear windows, colored lettering or

graphics or just a decorative and stylish

appearance to your part. Colors of the parts

from injection molding are easily changed to

allow using one mold to produce parts with

different appearances for product

differentiation |

|

|

| |

|

Benefits of two shot Moulding

[

Read more...

] |

|

|

|

|

>> According to

customers’ requirement, we can use the

imported high-quality plastic raw material

from manufacturer as follow

• GE • BAYER

• POLY • Chimei

• Santoprene •Dupont

>> We have

experienced many kinds of materials in

molding process. For example

• ABS • PC • ABS+PC

• PS • SAN • PP

• NYLON • NYLON+Glass Fill

• PMMA • POM •

PET

• TPE • TPR

• TPV • PU

|